PASS Information - ps:®hook

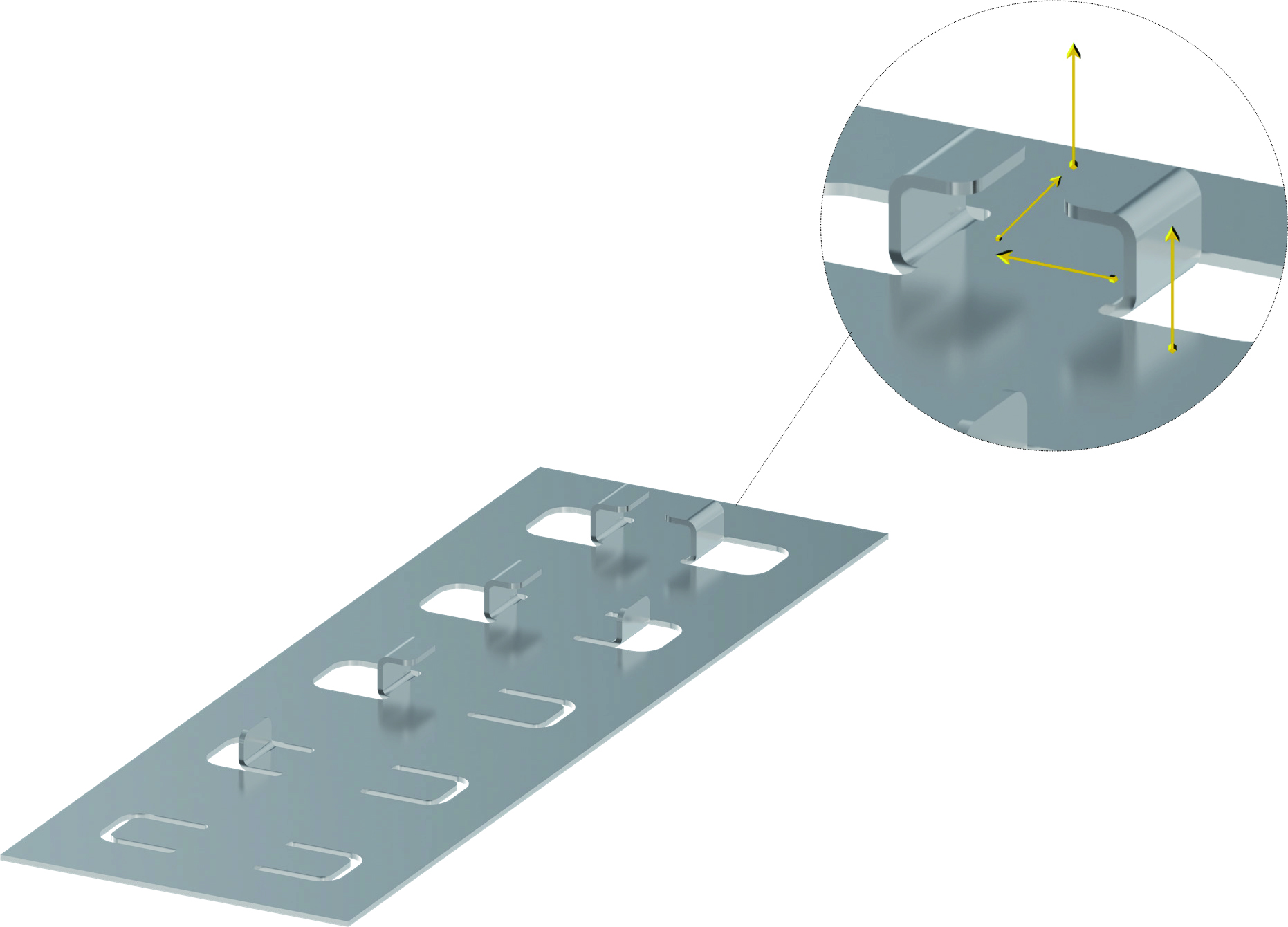

For the production of (double) bends in the smallest space

Conventionally, simple, long bends are produced on a bending machine. But when smaller bends or even double bends are needed in the smallest space, the daily production sometimes reaches its limits or is going to be inefficient and difficult or even impossible.

Basically, simple short bends can be produced on a punching machine with embossing-bending tools (for example our ps:®pivot for exact 90° bends). Our ps:®hook is perfect for U-shaped bends that require special programming.

How does it work? As usual, reliefs are required first. Then continue with the following steps:

|

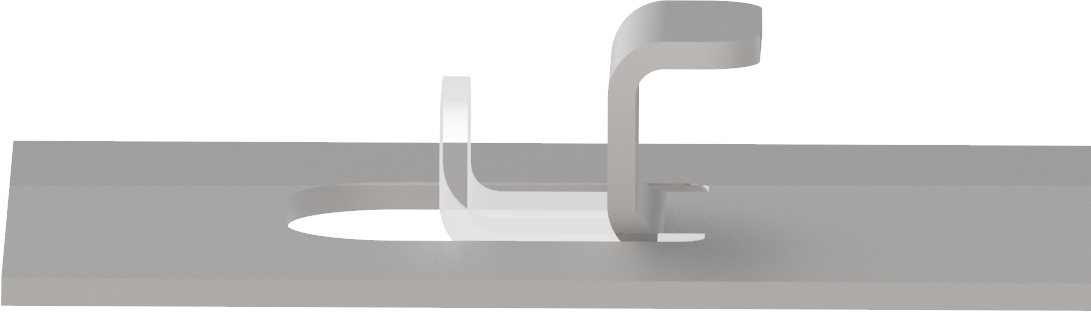

Step 1 The 90° bend is produced in the first hit. |

|

|

|

Step 2 Now the sheet metal is offset for another 90° (180°) bend. |

|

|

|

Step 1 - 2

|

||

|

In addition, ps:®hook also enables the production of double bends on a punching machine. |

||

|

Step 3 After completing steps 1+2, the tool is rotated |

|

|

|

Step 4 In order to complete the double bend, the sheet is |

|

|

|

Step 1 - 4

|

||

During the production of these bends, the tool must also be lifted and moved in a defined manner and requires precise programming.

If required by the customer to make double bends close together, the interaction of tool-machine-machine control programming is crucial.

PASS offers the perfect tool ps:®hook and of course the necessary support.

The example of a Prima Power machine shows the interaction of the 4 factors:

1. Tool

The tool was specially designed and manufactured for the Dif-station of the Prima Power Genius 1225. The upper part, which was manufactured with a special "shoe" for an exact 90° bend, gives the chance for a double bend for the smallest possible distance.

2. Machine

The machine must have an active die or forming station that the height of the double bends can be guaranteed. This allows a forming height of up to 14 mm.

3. Machine control

The example machine (Prima Power Genius 1225) is equipped with Tulus, which offers the possibility to add manual movement commands to the program (created by NC-Express). For ps:®hook, this manual programming function is a "must have" in order to be able to control the motion profile - movement and defined lifting of the tool - exactly.

4. Programming

Example programming for step 4 after bending the double bends:

- tool to -5 mm on Z

- sheet to 7 mm on X

- sheet to -10 on Y

- tool to -17 on Z

The topic of "double bending" is used in many different areas such as case construction, steel furniture, drawers, transport boxes etc.