PASS Information - ps:®big-knock-out

On-site knock-outs for large knock-outs

The topic of „knock-outs direct on bendings“ in order to break out pre-defined knock-outs properly and easily has already been solved with our ps:®knock-out.

However, knock-outs are also required for larger sizes. In this case, it is the best to work with connections which - depending on the application - can be connected more or less firmly to the sheet.

Typically, such work is still carried out on large presses.

PASS offers the possibility to integrate this external work process into the well-established CNC punching machines with tooling system TRUMPF, THICK TURRET or SALVAGNINI system. NOW these large on-site knock-outs can be produced during the complete punching process.

The solution is called: ps:®big-knock-out

FUNCTION:

The first tool cuts the sheet into segments and creates the desired quantity of connections onto the sheet. The quantity and arrangement of the connections are left to the machine operator. The second tool will cut the rest of the sheet between the pre-fabricated connections by nibbling.

SAMPLE:

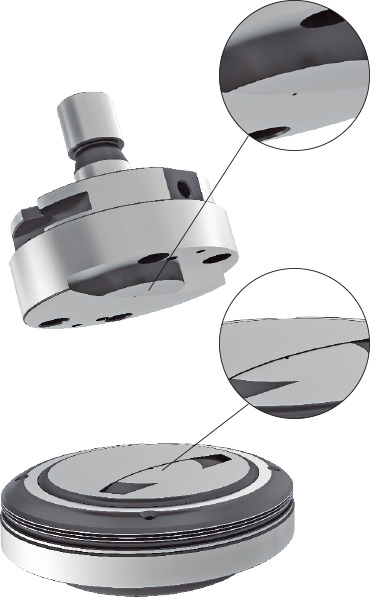

A 16-point connections is planned for round punching with Ø 1.000 mm. The tools for this purpose have been designed with a radius of r = 500 mm.

ADVANTAGES:

- connections for knock-outs with big diameter are now also possible for CNC punching machines established on the market

- ncrease of efficiency in production time and handling due to elimination of an additional external material handling

- free selectable quantity of connections

APPLICATION AREA:

- ventilation and heating construction

- large cabinet construction

- case construction

GENERAL:

- tools are individually designed for the required diameter

- possible sheet thickness: s = 0,5 to 2,0 mm

- possible sheet materials: aluminium, stainless steel, steel

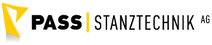

- tools are designed with internal ejector to ensure maximum process reliability

- emboss and cutting punch are designed with a large transition radius in order to create a smooth transition and minimize witness marks

|

|

| cutting tool for producing the connections |

continuous tool for connecting the pre-punched connections |

|

|

| The first tool cuts the sheet into segments and creates the desired quantity of connections onto the sheet. The second tool will cut the rest of the sheet between the pre-fabricated connections by nibbling. |