Low-scratch material handling: polish, brush, soft pads

There is often a problem with the die causing scratches on the sheet. Of course you can order steel with protective films, however there are other options with the tooling.

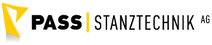

1. Polishing the die

The entire horizontal surface is polished. Furthermore, a large radius is blended onto the edge of the die and this is also polished.

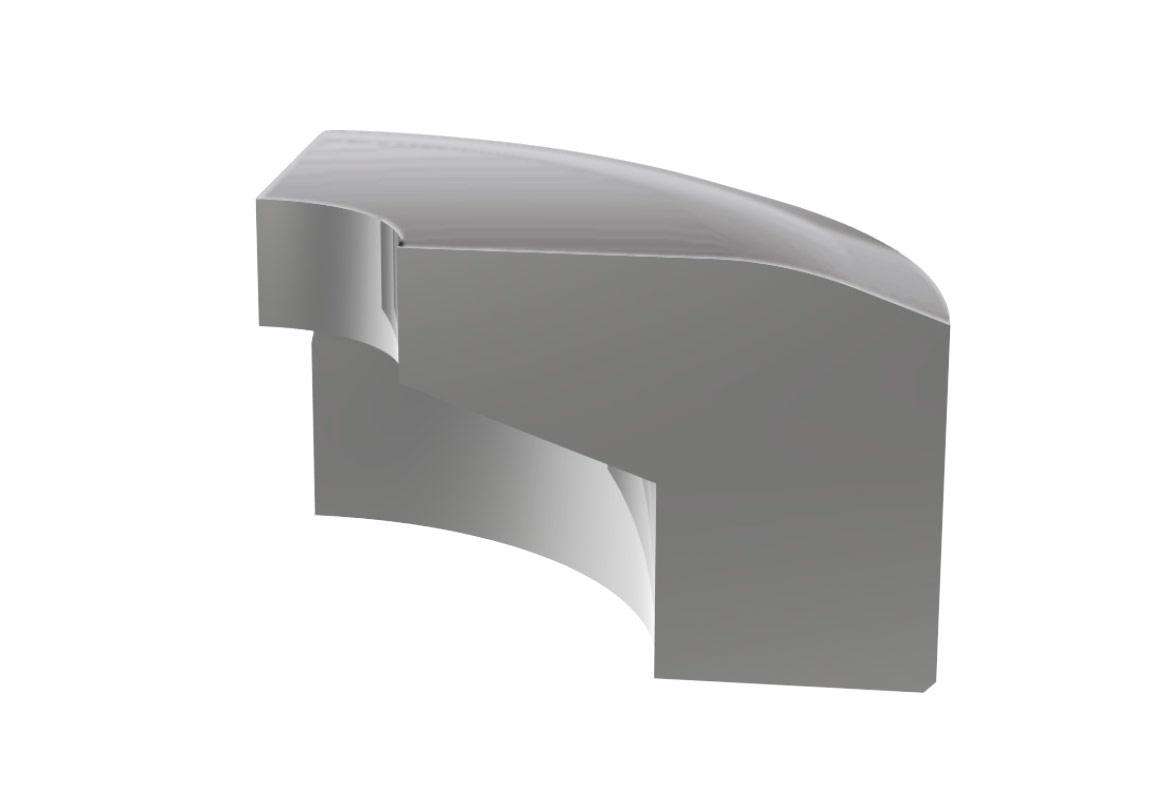

2. Adapter rings (for dies) with brush inserts

The adapter ring is fitted with a „brush ring“ with several brush inserts in order to lift the sheet above the cutting surface of the die.

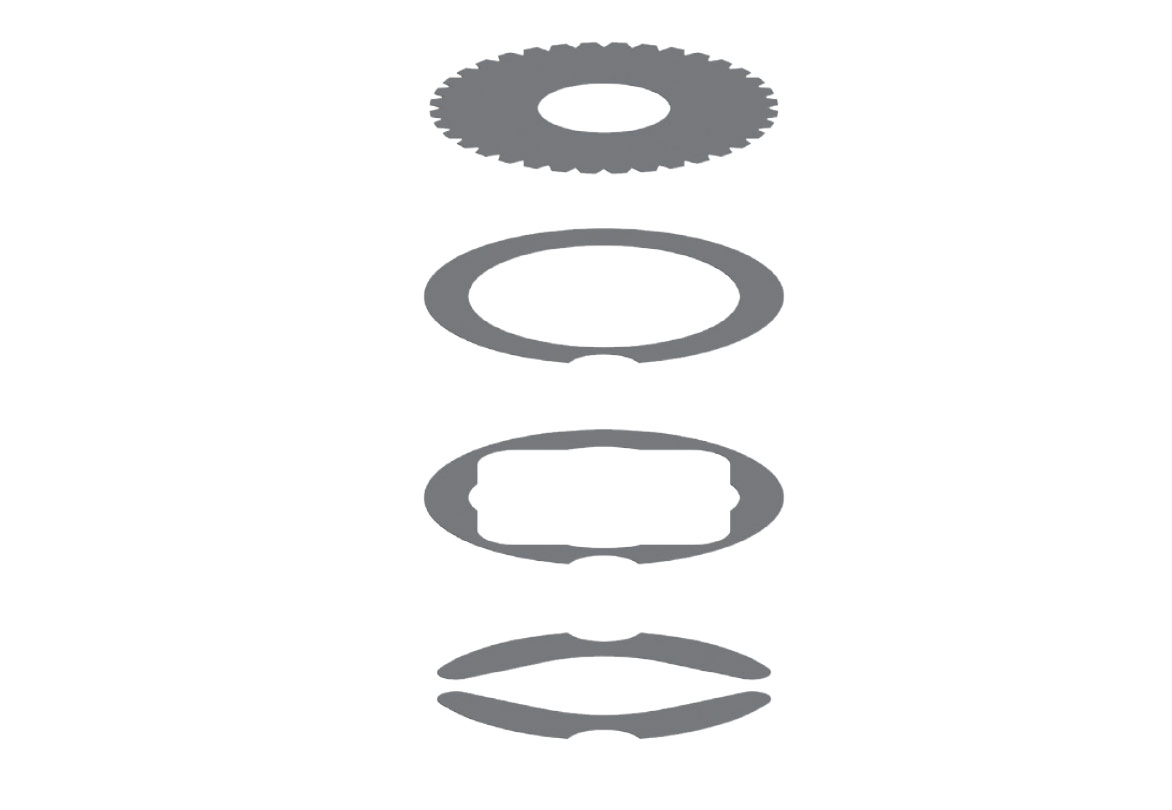

3. Using PASS Soft Pads

With a special foil pad which can be sticked directly on the die, stripper or adapter ring, scratches can be minimized. These pads are available in different versions.