PASS Information - Lifetime of tools

Lifetime of tools / regrind advices

"We have 120.000 hits to punch in a stainless steel with sheet thickness of s = 3 mm. How many punches do we need?"

or

"What is the operation time expected for nibbling aluminium sheet with sheet thickness of s = 1 mm?"

or

"At what quantity of hits should we regrind our tools?"

These kind of questions come to us daily for many years. Unfortunately the answers to all these questions are not easy to make as a lot of different factors have to be observed.

For approximately 30 years we collected technical information from our customers which allows references to be made for operation times of tools and regrinding times. Today we place this collected data at your disposal with the purpose to facilitate the estimated lifetime of tools.

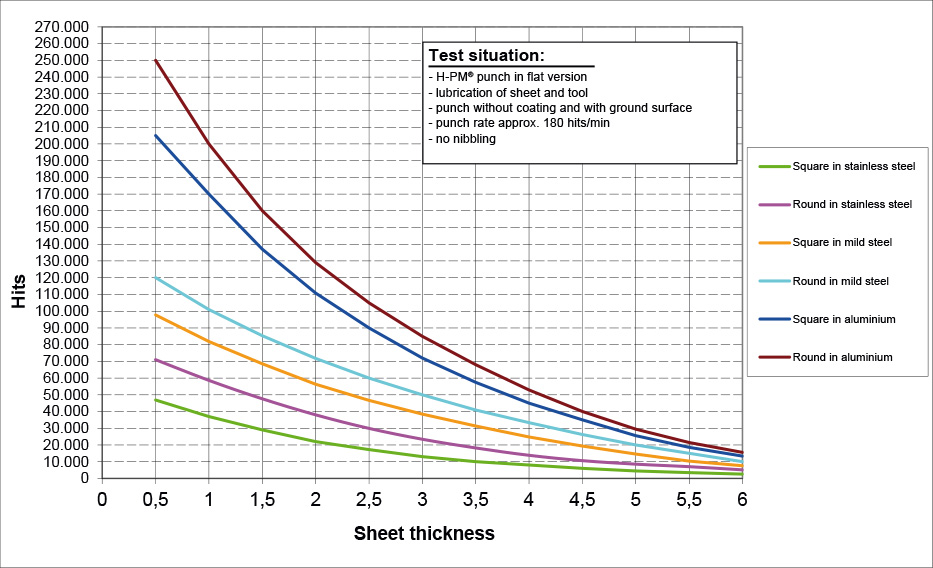

The following chart is compiled by indicating the recommended regrind after the relavant quantity of hits as there will be a difference for the regrind of the different machine types (tooling system).

The chart, however, should clarify as well that the punching process contains a big variety of influencing factors affecting possibly more or less the increase or decrease of the punching hits.

A precondition by using this data is preconditioned and optimal adjusted punching machine with with a solid C- or O- frame.

An average decrease of the tool life of 5-10 % per regrind has to be taken in account for the first regrind.

Influencing factors: |

factor |

| - Galvanised steel / stainless steel with foil / aluminium anodised | 0,5 - 0,8 |

| - No sheet lubrication | 0,4 - 0,6 |

| - Punch coating (TICN for stainless steel / T-MAX for galvanised steel / A-MAX for aluminium) | 2,0 - 4,0 |

| - PASS X3-PM punch | 6,0 - 10,0 |

| - Nibbling | 0,7 - 0,9 |

| - Notching | 0,5 - 0,7 |

| - Shear | 0,8 - 0,9 |

| - Punching rate > 300 hits / min. | 0,8 - 0,9 |

| - Cutting part with EDM surface | 0,4 - 0,8 |

| - Cutting part with polished surface | 1,5 - 3,0 |

| - Cutting part smaller than 1,5x sheet thickness | 0,6 - 0,8 |

| - Cutting part smaller than 1,0x sheet thickness | 0,3 - 0,5 |

| - Using of a too small clearance | 0,4 - 0,9 |

In the following example you will get an idea how the different influencing factors can effect the tool life:

Factors:

square punch / s = 2.0 mm stainless steel / nibbling / punching rate > 300 hits

A calculation can be variable depending of the factor which will be used:

Using the smallest factor (safety calculation):

22.000 x 0,7 x 0,8 = 12.320

(hit quantity (chart) x factor nibbling x factor punching rate > 300 hits) = lifetime

Using the biggest factor:

22.000 x 0,9 x 0,9 = 17.820

(hit quantity (chart) x factor nibbling x factor punching rate > 300 hits) = lifetime