PASS Information - ps:®wheel-straighten

Straighten tool for wheel beadings on TRUMPF machines

The PASS wheel tools ps:®wheel are available for a different range of applications, e.g. offset, deburring, reinforcing or beading tools, especially for large sheets.

The special feature of wheel beading tools consists of the segmented wheels whereby the tool can simply produce reinforced beads with a small radius. The wheels thereby work as a differential: The internal component rotates slower, the external turns faster than the center. Thus, the resulting thrust as well as chatter marks cease to appear. Furthermore, the segmented wheels contribute to a minimized sheet warpage through its operation.

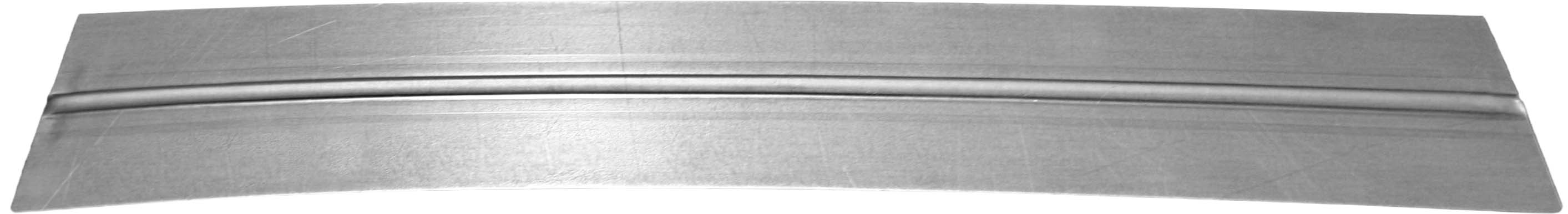

But occasionally it may be that a bigger sheet warpage occurs when producing a large number of beads in a row or beads of an enormous size.

In order to counteract this, PASS Stanztechnik AG has developped a solution:

Example image system TRUMPF

The straighten tool ps:®wheel-straighten for improving the mentioned sheet warpage is applied in combination with a wheel tool:

In the first step, the sheet is processed with a beading tool, in the second step ps:®wheel-straighten comes into action through which the occurred sheet warpage is counteracted through the integrated Ampco wheels. In practice this means that the sequence of beading and straighten alternates to reach the improved result on the sheet.

| sheet metal working with a wheel beading tool typical: sheet warpage upwards |

|

| sheet metal working with a wheel beading and a straighten tool improved flatness UT-OFFSET = 0 |

|

| sheet metal working with a wheel beading and a straighten tool sheet warpage downwards UT-OFFSET = -0,2 |

|

ps:®wheel-straighten will be adapted to customer needs as well as products and is available for the tooling systems TRUMPF and THICK TURRET. If you have any questions about the straighten tool ps:®wheel-straighten, please contact your contact person at PASS.